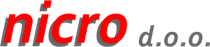

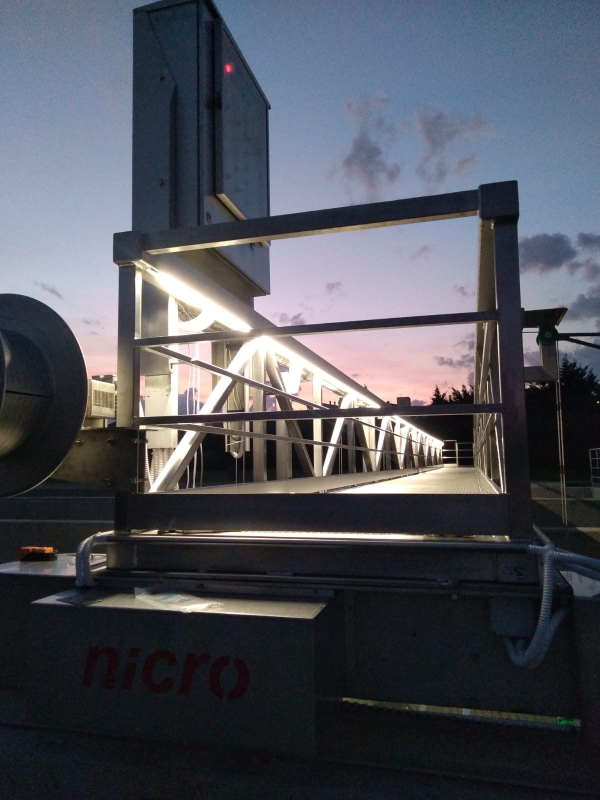

Creation of an executive project, production, supply and installation (assembly) of a complete logitudinal bridge crusher of subsequent settling tanks at the UPOV Center in Zadar.

Project asignment

The drawbridge with mud scrapers has a span of approx. 19.0 meters and extends over three parallel lines of the subsequent precipitator. It moves along two rails, each approx. 56.0 meters, anchored at the top of the edge walls of the subsequent clarifier basin. The construction of the bridge of the longitudinal crane is equipped with a floor and a protective double-sided fence with a handrail. An electric drive is provided for the moving parts of the longitudinal harvester.

Based on the Investor's request, it is necessary to create a mechanical design for the reconstruction of the longitudinal bridge crane made of stainless steel. The old bridge scraper needs to be dismantled, and a new one must be manufactured and installed. It is necessary to eliminate all the problems that occurred on the old bridge, such as the sticking of the left and right sides, due to the asymmetric movement of the bridge along the rails, and its jumping out of the rails.

Deviations in the parallelism of the concrete walls were found in the basin of the subsequent clarifier. That is why special attention should be focused on high-quality guidance (with the help of rails) in the longitudinal direction. In addition, the construction of surface and bottom mud scrapers should be adapted in such a way that they have greater lateral clearance, which is compensated by longer rubber inserts. The guiding of the bridge is ensured by the correct placement of the rails and wheels with a reinforced edge for guiding along the rails. Bottom mud scrapers must be supported on the concrete base by means of appropriate wheels.

In order to prevent corrosion caused by increased chloride content in waste water and air, the entire structure of the drawbridge must be made of stainless steel, AISI 316L/W.Nr. 1.4404.

After the assembly is completed, the bridge is tested ``dry'': the operation of the lower and surface screeds in the two end lines is checked and adjusted. The end lines are filled with clean water and the operation of the bottom and surface scrapers in the end lines is checked again. Only when the scrapers are adjusted to pass the full length of the subsequent clarifiers without getting stuck or scraped, is wastewater from the bioaeration basins released into the end lines again.

Then, emptying of the central line of the subsequent clarifier and installation of the bottom and surface scraper in it (with occasional interruptions in the operation of the movable bridge) is started. This is followed by testing the central line ``dry'' and ``wet'' with clean water.

When everything is adjusted, waste water is released into the central line of the subsequent clarifier.

Investor:

Odvodnja d.o.o.

Year of construction:

in 2019

Our clients and projects

Trust is based on experience. This also applies to products and services - and of course, above and beyond everything: the level of customer experience.